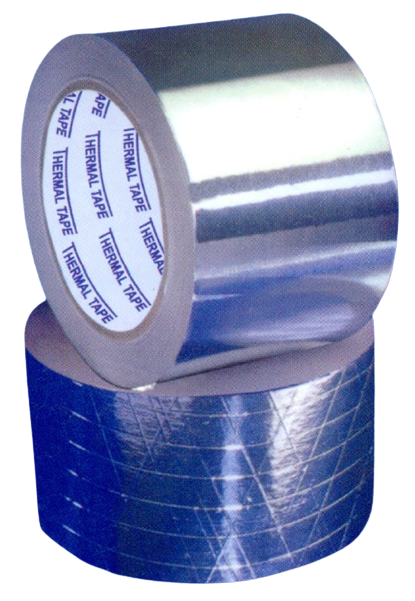

Seals Fiberglass Board Duct Joints

Wrinkle-Free, Conforms to Surface Irregularities

| art No. | Size | Pcs/Case |

| 2290 | 2 x 40 Yards3 x 40 Yards | 24/CASE16/CASE |

Product Information

Reinforced for Sealing Foil-Faced Duct Insulation Seams

Blends with Primary Facing for a Strong, Finished Look

| Part No. | Size | Pcs/Case |

| 3450 | 2 x 40 Yards3 x 40 Yards | 24/CASE16/CASE |